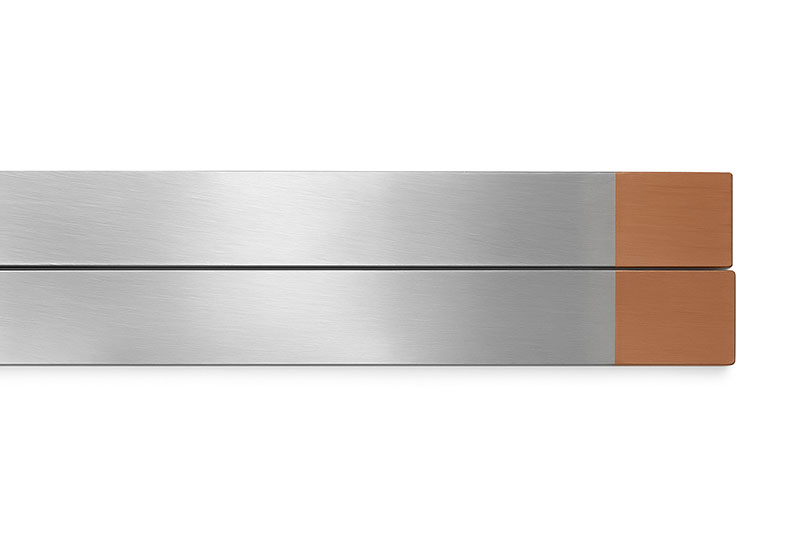

Copper to aluminum bus bar connections are critical components in modern industrial power distribution systems, providing efficient, reliable, and safe connection solutions for high power loads. Our connectors focus on addressing key customer concerns: mitigating galvanic corrosion through specialized coatings and clamps to ensure copper and aluminum busbar compatibility, thereby preventing premature failures.Utilizing copper for low resistance enhances efficiency, while incorporating aluminum reduces costs, providing design flexibility and durability.

Advantages

Efficient and reliable power transmission: Copper ensures efficient and reliable power transmission with its high conductivity and low resistance. By using a combination of copper and aluminum, our connectors can save energy while maintaining high efficiency, which is critical for power systems.

Cost-effectiveness: Aluminum has obvious advantages in weight and cost. Combined with copper, it not only reduces the overall material cost, but also reduces the weight of the system, helping to reduce transportation and installation costs.

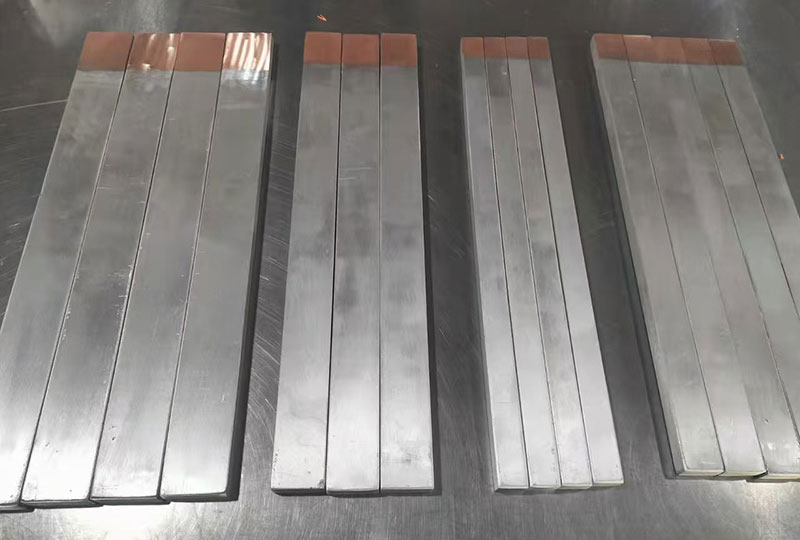

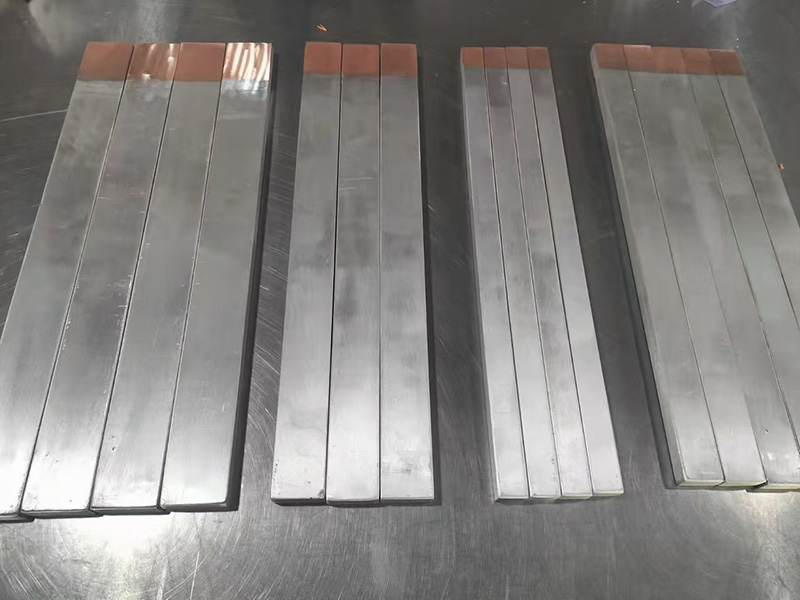

Prevent galvanic corrosion: We pay special attention to galvanic corrosion issues and use explosive welding processes to ensure long-term system compatibility and reliability, thereby avoiding premature failure.

Design flexibility: The combination of copper and aluminum provides design flexibility, enabling it to adapt to different industrial application requirements and meet the design and usage scenarios of diverse customers.

Application

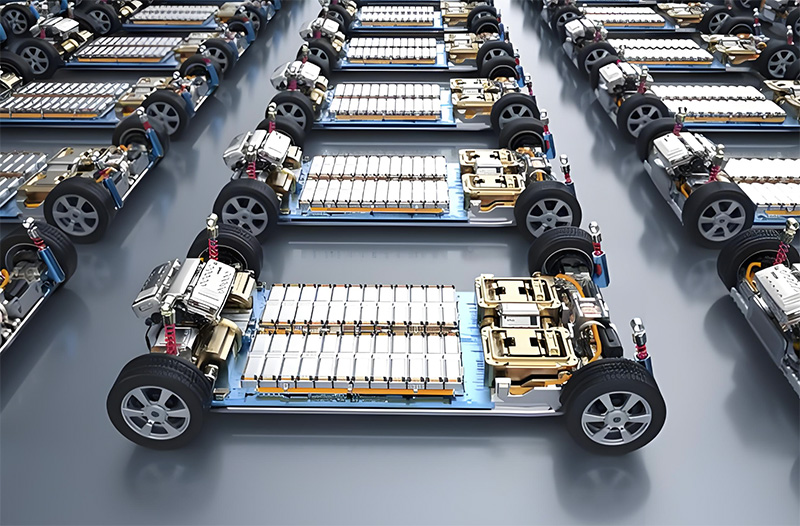

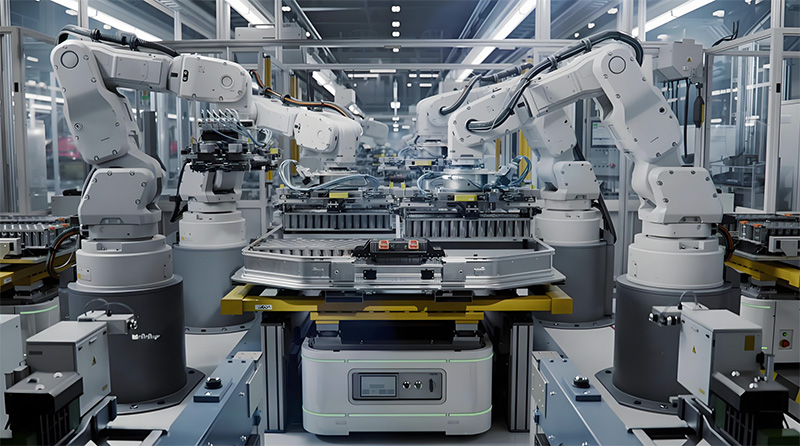

Electric vehicle battery system

Applicable to weight- and cost-sensitive electric vehicle battery packs. Aluminum reduces overall weight and improves energy efficiency. Copper ensures high conductivity of key contacts and meets the needs of high current transmission.

Renewable energy grid

In the distribution system of solar/wind power plants, the copper-aluminum composite structure balances high conductivity and equipment lightweight requirements, while reducing the cost of raw materials for large-scale grid deployment.

Industrial power infrastructure

Used in factory distribution cabinets, transformer connections and other scenarios, aluminum reduces the busbar cost of heavy equipment, and copper ensures stability in high-load areas, meeting the dual needs of industrial equipment for reliability and economy.

Electronic equipment and PCB manufacturing

In PCB board connections that require high-precision processing, aluminum is used to reduce processing costs for large-size conductive parts (such as heat dissipation modules), while retaining the low resistance characteristics of copper in the core circuit.

Railway transportation and ship power systems

Applicable to mobile vehicles (such as subways and ships) that are limited by space and weight. Aluminum reduces structural loads, and the copper-aluminum composite design meets the corrosion resistance requirements in humid/salt spray environments.

Parameter

Alloy | T2/1060/T2 |

Thickness | 4-30mm |

Copper layer thickness | 10% - 30% |

Width | ≤1000mm |

Length | Customized |

Alloy | T2/1060/T2 |

Thickness | 4-30mm |

Copper layer thickness | 10% - 30% |

Width | ≤1000mm |

Length | Customized |