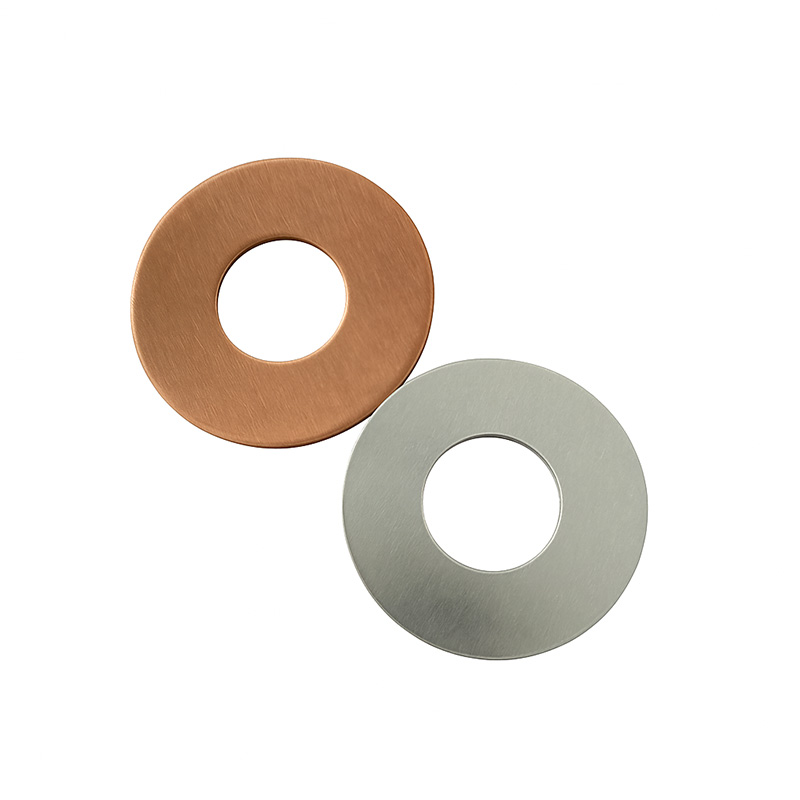

Bimetallic copper aluminum washer is a key transition component designed to solve the copper-aluminum connection problem. It is made of pure copper and pure aluminum firmly combined through advanced solid phase welding technology (such as explosion welding or friction welding), ensuring excellent conductivity and bonding strength.

Features

Eliminate corrosion and ensure long-term safe operation

Directly connecting the copper and the aluminum together will cause severe galvanic corrosion, resulting in increased contact resistance, heat, loose connection points and even burning, which seriously threatens the safe and stable operation of the power system.

Our bimetallic copper aluminum washer uses advanced bonding technology to form a stable, corrosion-free transition interface between copper and aluminum. This fundamentally prevents the occurrence of galvanic corrosion, ensuring the long-term reliability and safety of the connection point, and stable operation even in harsh environments.

Achieve low resistance connections and improve system energy efficiency

Improper copper aluminum connection methods will produce high contact resistance, which may cause the connection point to overheat, not only wasting electricity, but also causing fires, affecting the efficiency and safety of the entire system.

Our copper aluminum connection solutions ensure extremely low contact resistance at the copper-aluminum transition point through optimized material bonding surfaces and high-quality conductor materials. This minimizes power loss and heat generation at the connection point, improves current transmission efficiency, and ensures efficient and economical operation of the power system.

Optimize costs while maintaining excellent performance

Copper has excellent electrical conductivity but is expensive, especially when large, complex shapes need to be processed. Aluminum is cheaper, but copper's performance is necessary at certain connection points or in specific application scenarios. How can we ensure the performance of key connection points while controlling costs?

The bimetallic copper aluminum washer's connection solution gives you the flexibility to combine cost-effective aluminum with high-performance copper.It not only takes advantage of the economy of aluminum, but also ensures the superiority of copper connection.

Reliable, standardized connection method

How to correctly and reliably achieve the connection between copper and aluminum?

We provide mature and reliable copper-aluminum connection solutions that are widely used in the industrial field. Our products are carefully designed and rigorously tested to ensure the mechanical strength and electrical performance of the connection, avoiding the risks of trying unreliable connection methods.

Application

Used for electrical equipment

Scenario: This is arguably the most common application. In electrical switchgear, panelboards, transformers, and distribution systems, large aluminum busbars (chosen for cost and weight savings) often need to connect to copper busbars or copper terminals of devices like circuit breakers, switches, or contactors.

Purpose: Prevents corrosion at the junction, ensuring a long-term, low-resistance connection, reducing heat generation, and enhancing the safety and reliability of the electrical equipment.

Connecting aluminum cable lugs to copper busbars/terminals

Scenario: When aluminum power cables (terminated with aluminum lugs or sometimes bimetallic Cu-Al lugs) need to be connected to copper busbars or the copper terminals of electrical equipment.

Purpose: Facilitates the safe and reliable termination of cost-effective aluminum cables onto standard copper connection points, preventing connection failure due to corrosion and high resistance.

General Dissimilar Metal Junctions in Electrical Applications

Any situation where a copper component needs to be bolted directly to an aluminum component in a circuit or grounding system while maintaining good conductivity. Bimetallic copper aluminum washer acts as a transition layer, ensuring that copper only contacts the copper side of the washer and aluminum only contacts the aluminum side of the washer.

Purpose: Provides a standardized, reliable method for connecting dissimilar conductive metals in electrical assemblies, simplifying design and extending service life.

Parameter

Outside Diameter(mm) | 1 - 60 |

Inside Diameter(mm) | 1 - 21 |

Thickness(mm) | 1 - 4.5 |

Copper layer thickness | 5%,10%,15%,20%,25%,30% |

Copper alloy | T2 |

Aluminum alloy | 1060 |

Outside Diameter(mm) | 1 - 60 |

Inside Diameter(mm) | 1 - 21 |

Thickness(mm) | 1 - 4.5 |

Copper layer thickness | 5%,10%,15%,20%,25%,30% |

Copper alloy | T2 |

Aluminum alloy | 1060 |