Aluminium plate is a material processed by hot rolling or cold rolling process of aluminium ingot. The thickness is usually between 0.2-500mm, the width is more than 200mm, and the length is less than 16m.

According to the model, the aluminium plates we produce have three models: 5052, 5083, 6061.

According to the thickness, it can be divided into the following items:

Aluminium sheet : 0.15-1.5mm

Aluminium plate : 1.5-25mm

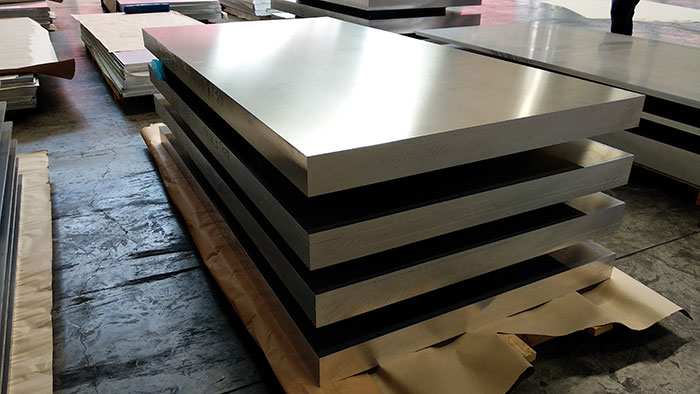

Thick aluminium plate : 25-200mm

Super thick aluminium plate : 200-500mm

Among them, 3mm aluminium sheet plate, 4mm aluminium sheet plate, 10mm aluminium sheet plate are the most sold.

3003 aluminum sheet plate for sale

3003 aluminum plate has good weldability, formability, and outstanding corrosion resistance. It is widely used in packaging, construction and other industries. The representative alloy states are H12, H14, H22, and H24.

5052 aluminum sheet plate for sale

5052 aluminium sheet plate is an aluminium-magnesium alloy plate. 5052 is a kind of rust-proof aluminium with medium strength, corrosion resistance and good fatigue resistance. It is usually used in transportation, hardware processing and other fields. The most common alloy model is 5052 h32.

5083 aluminum sheet plate for sale

5083 aluminium sheet plate is also a kind of aluminium-magnesium alloy plate. Its most outstanding performance is good corrosion resistance and good weldability. It is a typical marine aluminium plate, especially suitable for marine environment. Common models are 5083 h111, h112, h116, h321.

6061 aluminum sheet plate for sale

The main elements of 6061 alloy are magnesium and silicon, which have good strength and corrosion resistance, and are usually used in transportation, mechanical parts and other fields. The most common models are 6061 T6 and 6061 T651.

Aluminum sheet plate production process

1) Hot rolling process

The hot rolling process is gradually evolved from the method of semi-continuous casting, headcounting, milling, and then completing the processing of the product through multiple hot rolling on a single stand. Today's hot rolling mills are divided into single-stand single-coiler, single-stand double-coiler and multi-stand, and the thickness of the billet is rolled from 600-350mm to 8-2mm. The product range is: 1XXX, 3XXX, 5XXX, 7XXX, 8XXX series aluminium and aluminium alloy. Hot rolled products have a wide range, good quality and large output. The aluminium sheet and strip billets produced by hot rolling account for more than 65% of the total production worldwide.

2) Casting and rolling process

The casting and rolling process is a method of directly introducing molten metal into the gap between two internal water-cooled rotating rolls, and after crystallization, solidification and deformation, the strip is drawn from the other side of the rolls. It integrates a series of complex production processes such as casting and rolling, which greatly simplifies the hot rolling production process and opens up a new way for the production of aluminium processing strips. The casting and rolling mill can directly produce 5-12mm thick aluminium sheet coils from molten aluminium, which greatly reduces the production cost of aluminium sheets. However, due to the limitation of the length of the cooling zone and the limited cooling strength of the casting and rolling mill, the range of materials produced by the casting and rolling process is narrow, the amount of thermal deformation is small, the deep drawability is not good, the foil is easily broken during rolling, and the output is low.

3) Continuous casting and rolling process

Introduce molten metal aluminium into a pair of water-cooled circulating steel belts (including crawler belts), and directly cast into

The method of rolling an aluminium plate with a thickness of 20 to 30 mm into an aluminium coil by the rear 1 to 3 stands is called continuous casting and rolling. The range of materials produced by it is close to that of hot rolling, and the product performance is better than that of cast-rolled sheet, but worse than that of hot-rolled sheet.

Aluminum sheet plate for sale

The price of aluminium plate is related to the product model, product size, and order quantity. If you have demand for aluminium plate, please tell us the specific model, size, and quantity. As a professional aluminium plate manufacturer, we can ensure high-quality products and improve after-sales. At the same time, we will give you the most competitive price.