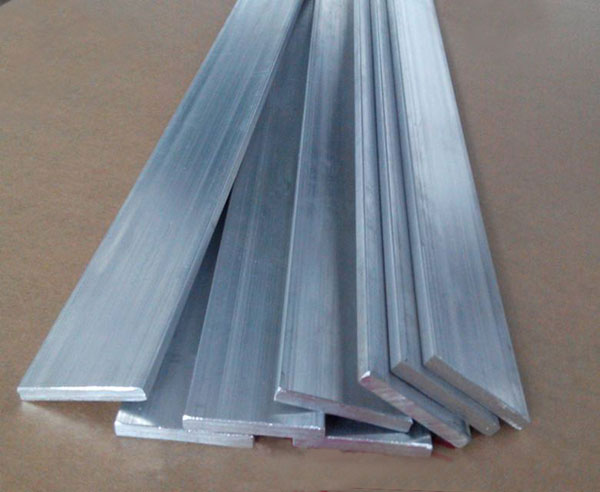

Aluminum bus bar brief

Aluminium bus bar is one of our leading producst,we offer high quality electrical grade aluminium busbars and provide complete solutions for you.

Aluminum bus bar is an aluminum product made of aluminum wire by drawing and extrusion.Its raw materials include high-purity aluminum wire, common aluminum wire and alloy aluminum wire, among which the aluminum content of high-purity aluminum bus bar is over 99.9%.

Aluminum bus bar is widely used in electrical equipment, also known as aluminum electrical busbar, it has many models, such as: 1xxx series, 5xxx series and 6xxx series aluminum bus bar.and the most common models are 1060 h112,1060 h24 and 6061 T6.

1xxx series aluminum bus bar usually have 1060 aluminum bus bar and 1070 aluminum bus bar. Compared with other types of aluminum busbars, they have the best electrical conductivity, are very soft, can be bent at 90 degrees without cracking, and have strong plastic processing performance. The most typical model is the 1060 aluminum bus bar.

The 5xxx series and 6xxx series aluminum bus bar are usually the most common 5052 aluminum bus bar and 6061 aluminum bus bar, which have better corrosion resistance, but have high strength and are not easy to bend. The most typical model is the 6061 T6 aluminum bus bar.

Why choose us?

* We have seventeen years of experience in the production and processing of aluminum bus bar.

* Our aluminum bus bars are made of high quality materials and do not use recycled scrap aluminum.

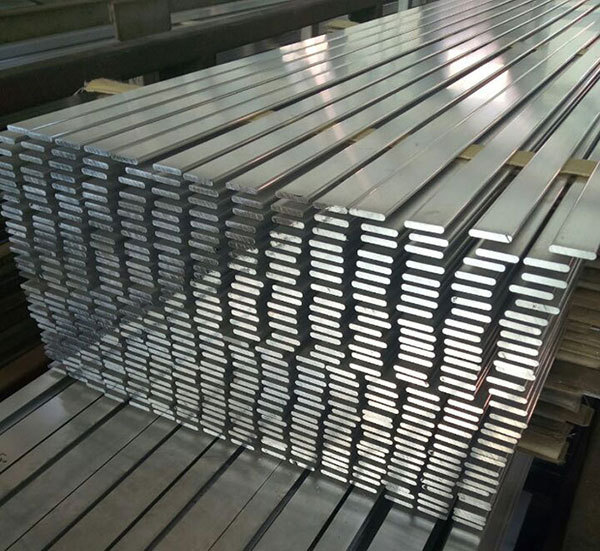

* Our aluminum bus bars are packed in plastic film and wooden boxes to ensure safety during transportation.

* There are many sizes of molds for aluminum bus bars.

* High production efficiency and fast delivery.

* Perfect packaging, plastic film and wooden box packaging, to ensure that the aluminum row will not be bumped and worn.

The advantages of aluminum bus bar

1. Light weight

The density of aluminum is only 2.7g/cm3, and the density of copper is 8.93g/cm3, so the density of aluminum is about 1/3 of that of copper, and its weight is lighter, which can reduce the weight load in electrical equipment applications.

2. Strong corrosion resistance

Under most environmental conditions, including air, water, petrochemical and other environments, aluminum has excellent corrosion resistance, greatly enhancing the service life.

3. High conductivity

Aluminum conducts electricity very well and is twice as conductive as copper on an equal weight basis.

4. High thermal conductivity

The thermal conductivity of aluminum is about 50-60% that of copper, which is beneficial for the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, and automobile cylinder heads and radiators.

5. Higher security

Aluminum is non-ferromagnetic and non-self-igniting, making it very safe, which is very important for electrical equipment applications.

6. Excellent formability and machinability

The workability of aluminum is excellent, and the tensile strength, yield strength, ductility and other properties of aluminum can be easily carried out for drilling, bending and other operations.

7. Economical

Aluminum is cheaper and has better economics than copper.

The current carrying capacity of the aluminum busbar

Aluminum busbar is used in electrical equipment, how to calculate its current carrying capacity? The current carrying capacity of the aluminum busbar is related to its cross-sectional size, and the current carrying capacity can be directly calculated according to the thickness and width of the aluminum busbar. At the same time, the current carrying capacity of the aluminum busbar is also related to the ambient temperature, the parallel, horizontal, vertical and other factors of multiple aluminum busbars.

Application of aluminum bus bar

aluminum bus bar is mainly used in electrical equipment, such as high and low voltage electrical appliances, switch contacts, power distribution equipment, and other electrical engineering. As a conductive bus, it has the advantages of low resistivity and large bendability.

Aluminum bus bar parameter

Alloys | Tensile strength Rm/Mpa | Yield strength Rp0.2/Mpa | Elongation % | Hardness HB |

1060 h24 | 105-145 | 75 | 3 | 33 |

6061 T6 | 260 | 240 | 10 | 85 |

AC current carrying capacity(A)

Size (width*thick) mm*mm | 25℃ | 30℃ | 35℃ | 40℃ |

15 x 3 | 165 | 155 | 145 | 134 |

20 x 3 | 215 | 202 | 189 | 174 |

25 x 3 | 265 | 249 | 233 | 215 |

30 x 4 | 365 | 343 | 321 | 296 |

40 x 4 | 480 | 451 | 422 | 389 |

40 x 5 | 540 | 507 | 475 | 438 |

50 x 5 | 665 | 625 | 585 | 539 |

50 x 6.3 | 740 | 695 | 651 | 600 |

63 x 6.3 | 870 | 818 | 765 | 705 |

80 x 6.3 | 1150 | 1080 | 1010 | 932 |

100 x 6.3 | 1425 | 1340 | 1255 | 1155 |

63 x 8 | 1025 | 965 | 902 | 831 |

80 x 8 | 1320 | 1240 | 1160 | 1070 |

100 x 8 | 1650 | 1530 | 1430 | 1315 |

125 x 8 | 1900 | 1785 | 1670 | 1540 |

63 x 10 | 1155 | 1085 | 1016 | 936 |

80 x 10 | 1480 | 1390 | 1300 | 1200 |

100 x 10 | 1820 | 1710 | 1600 | 1475 |

12 x 10 | 2070 | 1945 | 1820 | 1680 |

DC current carrying capacity(A)

Size (width*thick) mm*mm | 25℃ | 30℃ | 35℃ | 40℃ |

15 x 3 | 165 | 155 | 145 | 134 |

20 x 3 | 215 | 202 | 189 | 174 |

25 x 3 | 265 | 249 | 233 | 215 |

30 x 4 | 370 | 348 | 326 | 300 |

40 x 4 | 480 | 451 | 422 | 389 |

40 x 5 | 545 | 512 | 480 | 446 |

50 x 5 | 670 | 630 | 590 | 543 |

50 x 6.3 | 745 | 700 | 655 | 604 |

63 x 6.3 | 880 | 827 | 775 | 713 |

80 x 6.3 | 1170 | 1100 | 1030 | 950 |

100 x 6.3 | 1455 | 1368 | 1280 | 1180 |

63 x 8 | 1040 | 977 | 915 | 844 |

80 x 8 | 1355 | 1274 | 1192 | 1100 |

100 x 8 | 1690 | 1590 | 1488 | 1370 |

125 x 8 | 2040 | 1918 | 1795 | 1655 |

63 x 10 | 1180 | 1110 | 1040 | 956 |

80 x 10 | 1540 | 1450 | 1355 | 1250 |

100 x 10 | 1910 | 1795 | 1680 | 1550 |

12 x 10 | 2300 | 2160 | 2020 | 1865 |