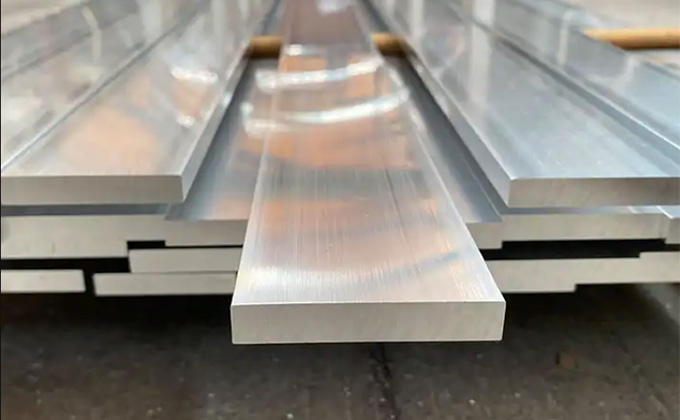

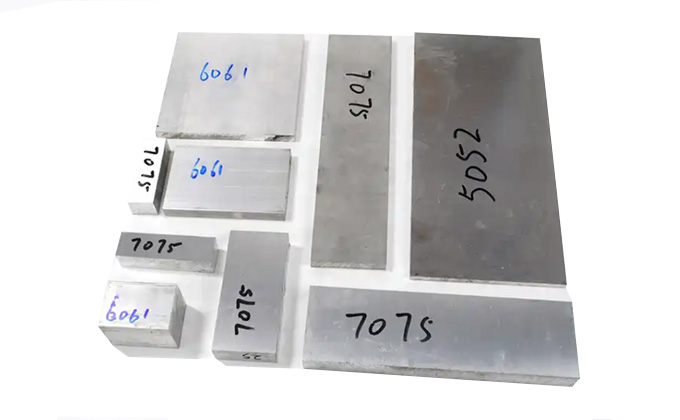

Aluminum flat bus bar is a type of aluminum profile, the shape is rectangular and produced by extrusion process, the most common aluminum flat bar alloy models are: 1060, 6061, 6101, 7075.

According to the shape, it can be divided into round corner aluminum flat bars and right angle aluminum flat bars.

Application of aluminum flat bus bar

Aluminum flat bus bar is mainly used in electrical equipment, such as high and low voltage electrical appliances, switch contacts, power distribution equipment, and other electrical engineering. As a conductive bus, it has the advantages of low resistivity and large bendability.

It can also be used in industrial support parts, ship materials and aviation parts, and mold manufacturing.

Why choose us?

Strong Production

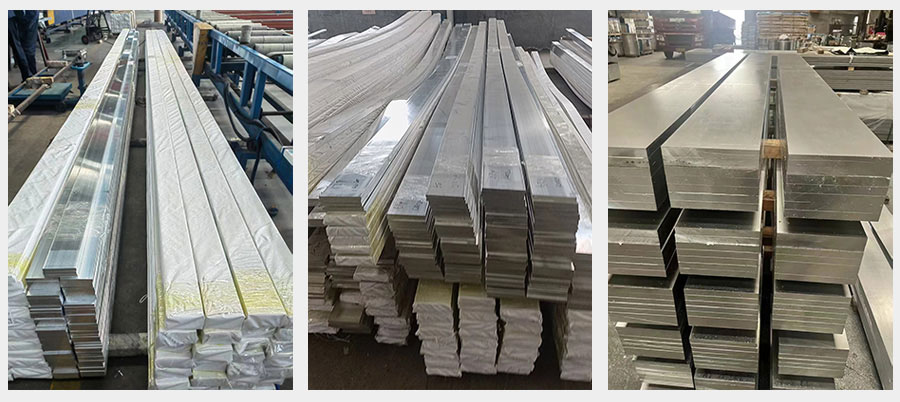

17 years of experience in aluminum flat bard production and processing, with 7 production lines and a monthly production capacity of about 1,000 tons,strict technical and quality inspection processes ensure that we provide you with high-quality products.

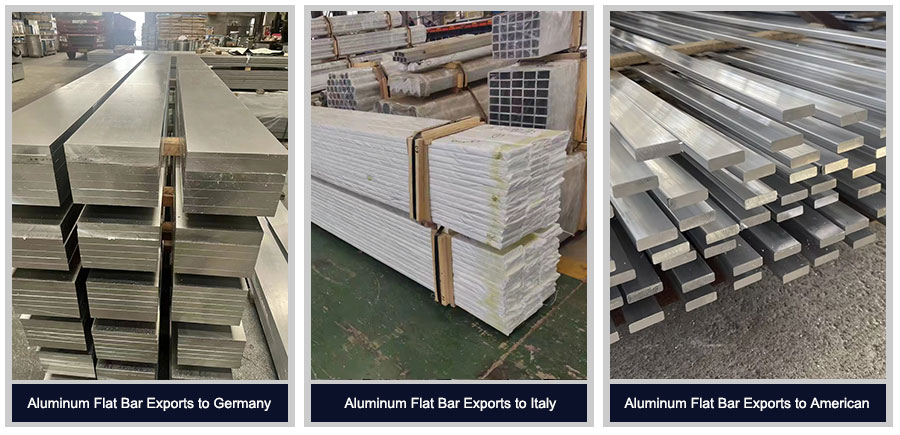

Reliable Exporter

Our products are exported to more than 50 countries around the world, provide you with a good purchasing experience in terms of product quality,packaging, delivery time, transportation, etc.

Large Inventory

A wide range of models and sizes are available in stock.

Our Case

Parameter

Aluminum flat bus bar parameter

Alloys | Tensile strength Rm/Mpa | Yield strength Rp0.2/Mpa | Elongation % | Hardness HB |

1060 | 90-165 | 34-145 | 25-35 | 19-28 |

2024 | 468-503 | 324-434 | 12-15 | 65-150 |

3003 | 117-207 | 41-172 | 20-30 | 28-40 |

5083 | 276-400 | 145-324 | 12-20 | 65-95 |

6061 | 262-310 | 241-276 | 8-12 | 95-120 |

6101 | 228-310 | 179-276 | 20-25 | 55-70 |

7075 | 262-310 | 241-276 | 8-12 | 95-120 |

AC current carrying capacity(A)

Size (width*thick) mm*mm | 25℃ | 30℃ | 35℃ | 40℃ |

15 x 3 | 165 | 155 | 145 | 134 |

20 x 3 | 215 | 202 | 189 | 174 |

25 x 3 | 265 | 249 | 233 | 215 |

30 x 4 | 365 | 343 | 321 | 296 |

40 x 4 | 480 | 451 | 422 | 389 |

40 x 5 | 540 | 507 | 475 | 438 |

50 x 5 | 665 | 625 | 585 | 539 |

50 x 6.3 | 740 | 695 | 651 | 600 |

63 x 6.3 | 870 | 818 | 765 | 705 |

80 x 6.3 | 1150 | 1080 | 1010 | 932 |

100 x 6.3 | 1425 | 1340 | 1255 | 1155 |

63 x 8 | 1025 | 965 | 902 | 831 |

80 x 8 | 1320 | 1240 | 1160 | 1070 |

100 x 8 | 1650 | 1530 | 1430 | 1315 |

125 x 8 | 1900 | 1785 | 1670 | 1540 |

63 x 10 | 1155 | 1085 | 1016 | 936 |

80 x 10 | 1480 | 1390 | 1300 | 1200 |

100 x 10 | 1820 | 1710 | 1600 | 1475 |

12 x 10 | 2070 | 1945 | 1820 | 1680 |

Aluminum flat bus bar parameter

Alloys | Tensile strength Rm/Mpa | Yield strength Rp0.2/Mpa | Elongation % | Hardness HB |

1060 | 90-165 | 34-145 | 25-35 | 19-28 |

2024 | 468-503 | 324-434 | 12-15 | 65-150 |

3003 | 117-207 | 41-172 | 20-30 | 28-40 |

5083 | 276-400 | 145-324 | 12-20 | 65-95 |

6061 | 262-310 | 241-276 | 8-12 | 95-120 |

6101 | 228-310 | 179-276 | 20-25 | 55-70 |

7075 | 262-310 | 241-276 | 8-12 | 95-120 |

AC current carrying capacity(A)

Size (width*thick) mm*mm | 25℃ | 30℃ | 35℃ | 40℃ |

15 x 3 | 165 | 155 | 145 | 134 |

20 x 3 | 215 | 202 | 189 | 174 |

25 x 3 | 265 | 249 | 233 | 215 |

30 x 4 | 365 | 343 | 321 | 296 |

40 x 4 | 480 | 451 | 422 | 389 |

40 x 5 | 540 | 507 | 475 | 438 |

50 x 5 | 665 | 625 | 585 | 539 |

50 x 6.3 | 740 | 695 | 651 | 600 |

63 x 6.3 | 870 | 818 | 765 | 705 |

80 x 6.3 | 1150 | 1080 | 1010 | 932 |

100 x 6.3 | 1425 | 1340 | 1255 | 1155 |

63 x 8 | 1025 | 965 | 902 | 831 |

80 x 8 | 1320 | 1240 | 1160 | 1070 |

100 x 8 | 1650 | 1530 | 1430 | 1315 |

125 x 8 | 1900 | 1785 | 1670 | 1540 |

63 x 10 | 1155 | 1085 | 1016 | 936 |

80 x 10 | 1480 | 1390 | 1300 | 1200 |

100 x 10 | 1820 | 1710 | 1600 | 1475 |

12 x 10 | 2070 | 1945 | 1820 | 1680 |